An Fengxue's blog : Hengda Perforated Metal Factory

Hengda is a full service manufacturer of perforated metal sheets and coils, also fabricated perforated metal products for various uses.

We have imported advanced machinery from Germany and Japan for Laser cutting metal sheet, digital control perforation, precision leveling of sheet, bending welding, painting finishes. We produce perforated coils in a wide range of width, aluminum perforated coils, galvanized perforated sheets and stainless steel perforated sheets in satin, bright and painted finishes.

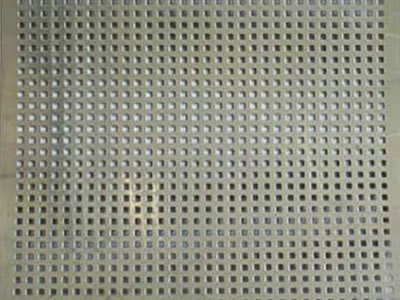

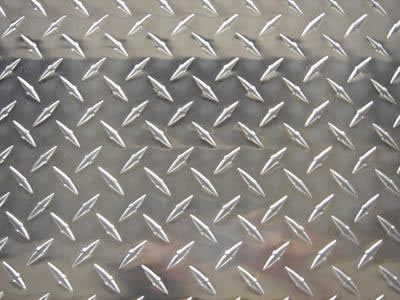

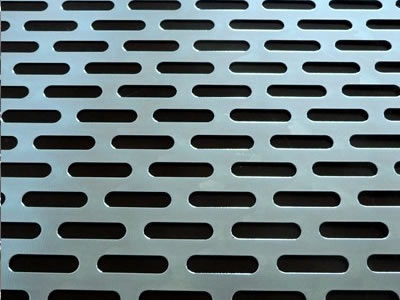

Perforated metal is a kind of sheet metal usually made with styles of perforating, embossing, slotting or checkered plates. The process of creating perforations is called perforating or punching. Perforated metal is a sheet or coil containing in itself holes punched according to a die pattern. Slotted perforated metal refers to metal sheets punched with a long narrow opening design. Embossing is a metal forming process for producing raised or sunken designs or relief in sheet material. Checkered plate, also known as Diamond plate, is a type of light-weight metal sheet perforated with a regular pattern of raised diamonds or lines.

We provide our customers with perforated metal sheets following specifications below:

We can provide the following materials for perforating:

Stainless Steel SUS 304 and 316, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals.

Specification

We can manufacture a wide rang of metal sheets with thickness verifying from 0.35mm to 3 mm and width maximum 1200mm. Length is the overall measurement of the long side of the sheet. Width is the overall measurement of the -short side of the sheet. The standard sheet size is 1000mm*2000mm. and 1000mm*2500mm. The coil width 1000mm is also available. We also can process the special product for your requirement.

The hole shape for perforated metal products:

Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc.

Sheet Metal Aperture

In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved. The minimum diameter we can fabricate is 0.8mm to 4 mm thickness . If you require a die that isn't already in our die bank, our experienced tool and die makers can quickly make exactly what you need at a reasonable cost.

Pattern

We offer perforated sheets with more options and less cost. Equipped with computerized-programmable feed systems, we will expand your custom design options.

Our Perforated Sheet is available in the following patterns:

Round, square, oblong, triangle, slot, hex, oval, louve, diamond and a broad variety of special shaped holes. We have tooling available for many different hole patterns and shapes. It is more economical to choose one of the available patterns, although special hole sizes and patterns can be accommodated at additional cost.

Pitch

Hole center is the distance from the center of one hole to the center of the nearest hole in the next adjoining row.

Open area

Open area is the total area of the holes divided by the total area of the sheet and is expressed as a percent , Keep in mind that punching holes in a material add stresses that can result in distortion of the product. The higher the open area, the more material distortion takes place, especially when the perforated pattern is bordered by margins on all four sides. But these distortions can be removed by our special in house leveling process.

Margins

Margins are the blank area along the edges of the sheet. If you want the product with special margins, you should provide the width of each margin on all four sides (measured from the edge of the sheet to the edge of the first hole).Manufacturing considerations may affect margins. If the margins requested are not possible. We will replace it with the similar products as your consideration.

Tolerances

There are tolerances on thickness, pitch, openings, flatness, and shearing for perforated products. You should specify a specific tolerance ,so we can give you a precise product. If not, we will according to standard tolerance.

Quality and Control: We utilize first-class software to plan, schedule, track and report each job that flows through our plant. It manages the life-cycle of quality control and continuous improvement events.

Capabilities: We supply various perforated sheets as well as finished perforated metal products such as filter tubes, security screen, architectural mesh and infill panels. We are committed to producing the highest quality parts on time and at a competitive price. We have over 10 years of manufacture experience. Our products cover perforated metal sheets, perforated screen, perforated panels, tubes, expanded metal, and perforated metal machines. We have also developed new types of metal sheet products, Slotted Liner and Bridge Slotted Screen Pipe, mainly for sand control in water wells and oil wells. Hengda perforated plate can be punched into discs for filter elements and metal sheet sieves for testing and laboratory analyzing.

MAJOR APPLICATIONS

Perforated Materials for Architectural Metal Works

Perforated Aluminum Sheet for Facade and Balustrade Panels featuring light weight and decorative effect.

Perforated mesh screen product for Gantry works, escape stairs / ladders / platform / handrails / staircases / walkways.

Staircase styles including Straight stairs, Curved stairs, Fire escape stairs in hot dip galvanised, stainless steel or aluminum painted finishes.

Perforated Metal Grille for Architectural Vent System: We can supply perforated metal vent grille covers in various shapes, sizes, hole shapes and styles. Hole shapes can be round, diamond or decorative designs. Uniform sheet thickness, hole sizes and a wide choice of finishes to fit different architectural design requirements.

Perforated Metal Angle Beads - Building Material: Offering More Precision in Uniform Surface Plastering compared with expanded metal beads. Good shaping and trimming function. Designed for wall corners plastering and reinforcement. Used against chipping and cracking of wall construction. Mostly made of round hole perforated stainless steel, galvanized steel or aluminum sheets.

Perforated Metal Angle Beads - Building Material: Offering More Precision in Uniform Surface Plastering compared with expanded metal beads. Good shaping and trimming function. Designed for wall corners plastering and reinforcement. Used against chipping and cracking of wall construction. Mostly made of round hole perforated stainless steel, galvanized steel or aluminum sheets.

Perforated Tubes for Filter Elements

Filter Elements: Stainless steel perforated sheets with embossed round holes welded to form tubing for protection sleeves uses. Material grades can be SUS304, 304L, 316L, Monel Steel, Inconel, Hastelloy, Aluminised Steel and Galvanised Steel. Hole patterns can be popular round or square holes. Gauges varies. Full perforated with a full end at one end or other choice depending on specific filter requirements.

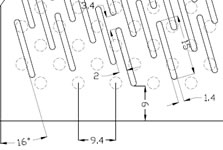

Slotted Filter Sheets: A kind of precise opening perforated filter products. 316 stainless steel material. Supplied in slotted sheet form, or fabricated tube or other filter forms. Detailed drawings with technical parameters such as slot width, length, tolerance, sheet thickness are welcome with your order.

Slotted Filter Sheets: A kind of precise opening perforated filter products. 316 stainless steel material. Supplied in slotted sheet form, or fabricated tube or other filter forms. Detailed drawings with technical parameters such as slot width, length, tolerance, sheet thickness are welcome with your order.

SS Perforated Screens: Perforated Screen in Stainless Steel used as Polisher Screen, Grader Screen, Hammer Mill Screen for Corn / Grains Milling. Oblong holes. With or without shielding according to specific uses. Stainless steel 304 or 202 grade is chosen depending on different hardening consideration of work condition requirements.

Windproof Perforated Metal Nets - Highway Fencing, Wind and Dust Control

Perforated metal wind-breaking nets have peaks and lower area. Punched with big and small holes in different parts of the sheet. It is strong and can be used to protect the environment from strong winds and dusts especially in sandy areas and highways where there is high speed winds.

Please contact us today with your requirements.

In:- Jobs